FabLink® is your standard-compliant solution for implementing SEMI standards for vertical integration of production equipment in accordance with the SEMI Generic Equipment Model (GEM), GEM300 and EDA standards. With SEMI-compliant interfaces, you can quickly and easily integrate your machines into semiconductor, PCB, LED, flat panel and OLED factories. The SEMI PV standard, adapted to the photovoltaic industry, is is used for integration in photovoltaic factories, and the SEMI A3 standard enables shop floor communication in PCB manufacturing.

FabLink® – Your benefits

-

- Reduced development costs

- Quick and easy implementation of SECS/GEM, GEM300, PV2, SEMI A3 and EDA (Interface A)

- Save time with pre-prepared SEMI documentation

- Implement your own follow-up projects quickly

-

- Training, requirements analysis, consulting, implementation, commissioning and support by experienced experts

- Support in implementing customer-specific requests and specifications

-

- More than 16,000 installations

- Continuous product development

- More than 20 years of expertise

Features at a glance

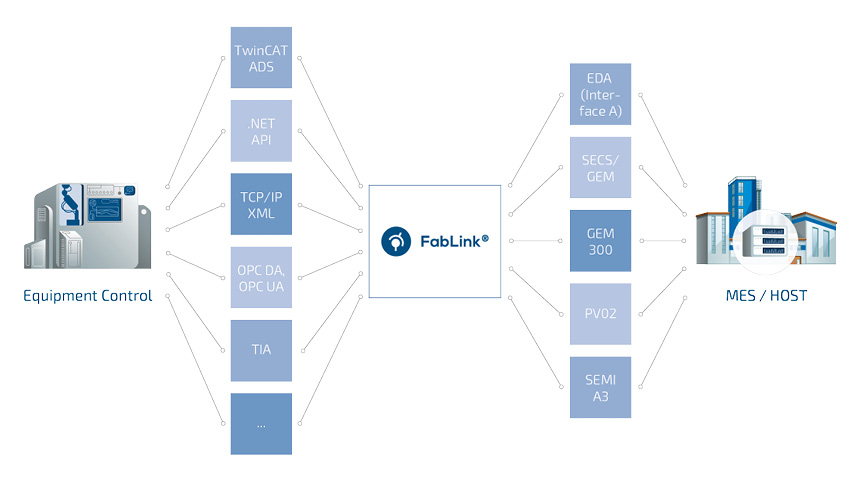

FabLink® builds on the equipment control and supports a wide range of protocols and control types. It opens up the world of SEMI-compliant integration for your machines with SECS/GEM, GEM300 and EDA (Interface A). In addition, we offer you a high degree of flexibility in the implementation of spooling, limits monitoring and terminal services functions.

With FabLink® Designer, we support the easy and clear configuration of the SECS/GEM interface for various equipment series. The pre-prepared interface documentation (GEM manual) in open file format enables custom adaptation so it is quickly ready for the factory operator.

Your path to equipment integration

Flexible FabLink® integration solution enables you to establish communication between machine and factory IT (e.g. host system) through various standards, interfaces and PLC systems.

| Interfaces, e.g.: | PLC, e.g.: |

|---|---|

|

|

Supported SEMI standards

- E4 SECS I

- E5 SECS II

- E30 GEM

- E37 HSMS

- Documentation

- E167 Specification for Equipment Energy Saving Mode Communications (EESM)

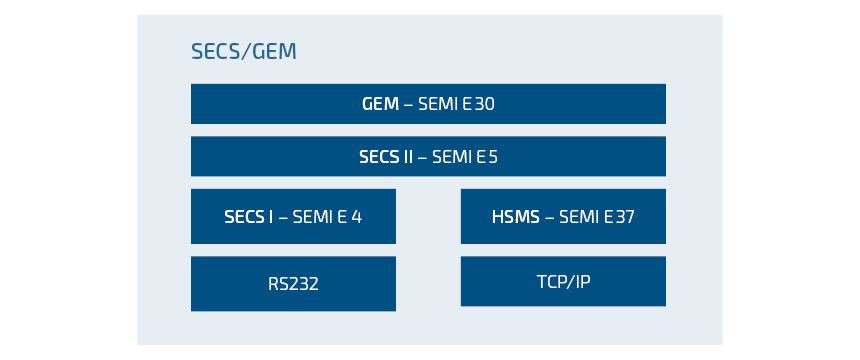

SECS/GEM is a group of communication standards developed by Semiconductor Equipment and Materials International (SEMI). SECS is an abbreviation for SEMI Equipment Communication Standard. GEM stands for Generic Equipment Model and refers to the E30 SEMI-connectivity standard and defines a generic model for communication and control of production equipment. SECS/GEM provides a uniform interface for communication between automated equipment and the host. The communication standard was developed primarily for the semiconductor industry, but is also used in PCB and LED, flat panel and OLED factories.

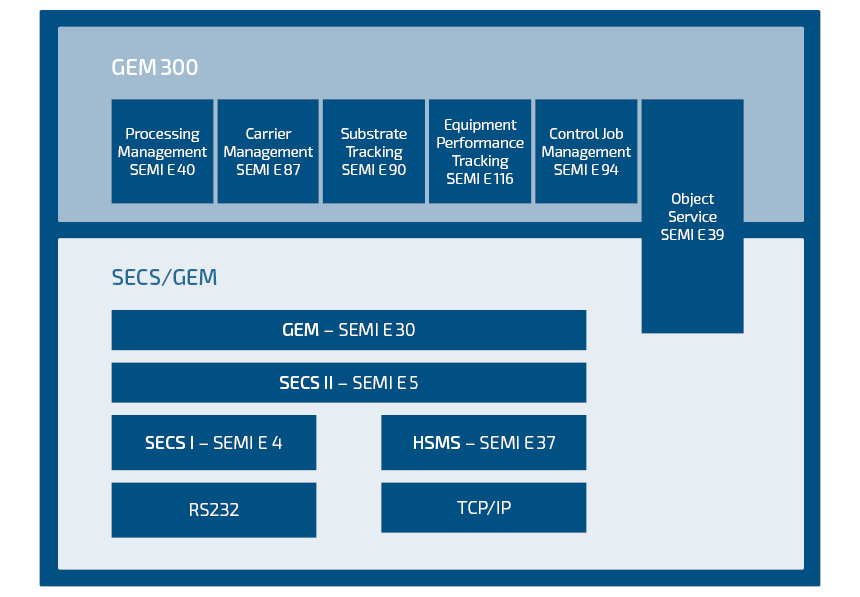

The SECS protocol architecture consists of several layers. The first SECS layer is based on the RS232 interface (SEMI E4) or the TCP socket (SEMI E37). The higher SECS I and HSMS level is primarily responsible for connection management between host and equipment. The SECS II (SEMI E5) and GEM (SEMI E30) protocols for data exchange using standardized messages are located at the upper hierarchy levels. This layer model enables the machine to provide the host with information such as status and data variables, events, and alarms. The manufacturing execution system (MES) can use this information to monitor production, adjust the parameters if necessary and provide management with useful information using the monitoring function.

- E39 Object Service

- E40 Processing Management

- E87 Carrier Management

- E90 Substrate Tracking

- E94 Control Job Management

- E116 Equipment Performance Tracking

While the SECS/GEM standards are used for factories with a low degree of automation, high-end production, including automated material transport within the factory (e.g. AGV or OHT), requires further standardization in accordance with GEM300 standards. These are based on SECS/GEM standards and are used, for example, for detailed tracking and approval of carriers and individual substrates (SEMI E87) or for differentiating control jobs (SEMI E94) and process jobs (SEMI E40), with the control jobs assigning individual substrates to process jobs that involve different recipes. The individual substrates within the machine are tracked in detail (SEMI E90). In addition, detailed performance monitoring of the machine with all its modules is possible (SEMI E116). This ensures full control over the production at all times.

- E120 Common Equipment Model

- E125 Equipment Self Description

- E128 Specification for XML Message Structures

- E132 Authentication and Authorization

- E134 Data Collection Management

- E138 Semiconductor Common Components

- E145 Classification for Measurement Unit Symbols in XML

EDA (Equipment Data Acquisition), also known as Interface A, is an additional interface standard in the semiconductor industry that combines various SEMI standards. Modern semiconductor factories need high volumes of equipment and process data to optimize production. EDA was developed to collect data from the equipment. In contrast to a bidirectional SECS/GEM interface, which also makes it possible to control an equipment, EDA focuses exclusively on providing high volumes of data. EDA therefore represents a second machine interface in addition to SECS/GEM or GEM300. The collected data forms the basis for optimizations, which can be implemented with AI tools, for example.

- Guide for PV Equipment Communication Interfaces (PVECI)

PV2 standard specifies a uniform IT interface for production equipment in the photovoltaic industry. The standard is largely based on the established framework of SECS/GEM norms and has been adapted to the specific needs of the industry. This promotes the use of powerful software systems in the area of factory control and management. SEMI PV2 enables factory IT systems such as manufacturing execution systems (MES) to access production machines and adjust their process parameters. In addition, the uniform interface provides, among other things, measurement, process and performance data for the machines.

- A3-0819 Specification for Printed Circuit Board Equipment Communication Interfaces (PCBECI)

In 2019, SEMI A3-0819 Specification for Printed Circuit Board Equipment Communication Interfaces (PCBECI) standard was published by SEMI. The SEMI A3 standard is an industry-specific adaptation of SECS/GEM standards to electronics manufacturing and describes a standard interface in PCB manufacturing for bidirectional communication between machine and host. In order to simplify data management, some SECS/GEM functionalities have been limited. SEMI A3-0819 therefore offers a robust, comprehensive and expandable standard for shop floor communication.

The SEMI standards, such as SECS/GEM and GEM300, define the rules for communication between factories and production plants. They ensure that machines and systems interact smoothly with each other. The SEMI standards are not only relevant for the semiconductor industry, but also for photovoltaic and electronics production. They provide a clear structure and guidelines to improve efficiency, quality and interoperability. Further information on the SEMI standards can be found here.

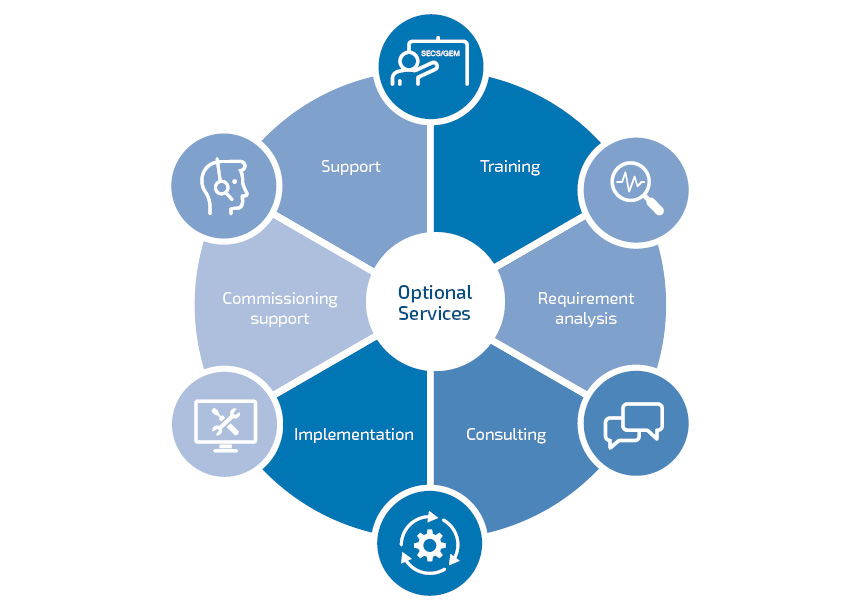

Our services for your equipment integration

Thanks to FabLink®, you can connect your machines quickly and in accordance with the standards. Once you have successfully implemented the first project, all machine-specific configurations can be implemented quickly in subsequent projects without further assistance. However, since the implementation of an equipment interface according to the SEMI standard can be very complex and not very transparent, especially at the beginning, we provide you with support throughout the entire process of equipment integration. You can simply put together the right services you need from our extensive portfolio.

-

Training

Our introductory training courses and a follow-up project-specific workshop will provide you with the knowledge you need for your project. In order to implement your specific requirements independently in the future, we also offer comprehensive product training so that you can configure additional SEMI-compliant interfaces yourself.

-

Requirements analysis

We evaluate the specifications and compliance documents provided by your customers for you. Based on our experience, we analyze the relevant requirements on a machine-to-machine basis.

-

Consulting

In order to assist you during the project, we advise and support you in implementing the software.

-

Implementation

Depending on the requirements, you can implement your SECS/GEM interface yourself or let us do it for you.

-

Commissioning

On request, we will accompany you through to commissioning — either at your site or at your customer's.

-

Support

Even after the project has been completed, we will support you with future feature updates and with product or project support.

Areas of application of SEMI standards in mechanical engineering

Integrate your equipment conveniently, quickly and in compliance with complex SEMI standards. Make your mark on the innovative semiconductor market in all stages of automation by implementing your SECS/GEM, GEM300 and EDA interfaces.

Integrate your equipment in factories in the photovoltaic industry in accordance with the required SEMI PV02 standard.

Integrate your equipment with PCB manufacturing IT systems by using the SEMI A3 standard.

Your contact person